In-depth Analysis on Common Problems and Solutions in Lift Fixing

In the world of lift repair service, a careful examination of typical concerns and their equivalent solutions is extremely important to making certain the seamless operation and safety and security of these necessary vertical transportation systems. From the troublesome problems with elevator doors to the complex intricacies of electrical malfunctions, a myriad of difficulties can torment lift functionality (lift repair). As we explore the complexities of lift maintenance, a detailed understanding of these issues and the reliable strategies for fixing them becomes an essential facet of guaranteeing optimum lift efficiency

Lift Door Issues

Among the most common challenges come across in lift upkeep is resolving lift door breakdowns. The smooth procedure of lift doors is crucial for passenger safety and effectiveness. A malfunctioning door can result in delays, aggravation, and also possible threats.

Lift door problems can originate from various factors, such as faulty door sensors, misaligned doors, damaged rollers, or concerns with the door driver device. These breakdowns can lead to doors closed or closing appropriately, getting stuck midway, or perhaps shutting also swiftly, presenting a danger to travelers going into or exiting the lift.

To address lift door breakdowns efficiently, maintenance specialists should conduct normal examinations, lube moving components, adjust door timings, and replace damaged elements quickly. Furthermore, carrying out precautionary maintenance schedules can aid determine and fix possible door problems prior to they escalate. By prioritizing lift door upkeep and quickly dealing with breakdowns, structure owners can make sure the efficient and safe procedure of their lifts.

Electric Malfunctions

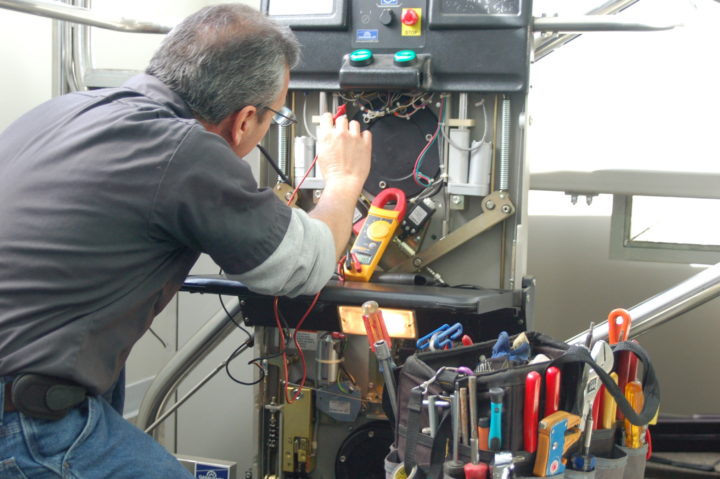

Attending to electric malfunctions in lifts requires comprehensive analysis evaluations and specific troubleshooting methods to guarantee the reputable and safe performance of the elevator system. Electrical breakdowns can manifest in numerous methods within a lift system, varying from concerns with the control board, faulty electrical wiring, power supply problems, to troubles with interlocks and sensors. When encountering electric malfunctions, it is essential for upkeep personnel to follow a methodical approach. This includes checking the power supply to the lift, checking wiring for any kind of indications of damages or wear, and testing the capability of essential elements such as the control board and emergency stop switch. Making use of analysis tools such as multimeters and circuit testers can assist in pinpointing the origin of the electric breakdown accurately. In addition, making sure that all electrical links are safe and helpful resources secure and up to code is necessary in stopping future breakdowns. By dealing with electric problems without delay and effectively, lift technicians can maintain the safety and performance of lift operations.

Hydraulic System Troubles

A malfunctioning pump can lead to the lift not being able to produce adequate hydraulic stress to linked here run successfully. Regular inspection, upkeep, and timely replacement of hydraulic parts can stop these issues and ensure the smooth functioning of the lift system.

Control System Problems

Control system breakdowns can disrupt the smooth procedure of lift systems and posture safety dangers if not promptly attended to. When the control system stops working to connect effectively with the lift elements, it can result in erratic motions, unanticipated quits, or total closures.

To attend to control system problems, lift repair professionals should perform detailed diagnostics to identify the root cause of the concern. By quickly resolving control system breakdowns, lift drivers can guarantee the safety and security and reliability of their systems for guests and protect against pricey downtime.

Safety Includes Concerns

In making sure the optimum functionality of lift systems, watchfulness in the direction of the honesty of security features becomes vital complying with the identification and resolution of control system problems. Safety and security features in lifts are created to stop mishaps, breakdowns, and injuries. Usual concerns connecting to safety and security attributes include issues with door sensing units, emergency situation brakes, overload sensing units, and try this out fire-rated touchdown doors. Door sensors are important for detecting blockages and guaranteeing doors do not close on guests. Emergency brakes are crucial for stopping the lift in instance of a mechanical failing. Overload sensors assist stop the lift from operating when it surpasses its weight capability. Fire-rated landing doors are vital for containing fires and shielding occupants during emergencies. Normal maintenance, examinations, and testing of these safety and security features are important to guarantee they are functioning appropriately. Attending to security attribute problems immediately can significantly reduce the threat of mishaps and improve the general safety of lift operations.

Conclusion

To conclude, usual concerns in lift fixing include elevator door issues, electric malfunctions, hydraulic system troubles, control system problems, and safety and security features problems. It is important for upkeep teams to address these concerns promptly to make certain the effective and secure operation of elevators. By applying appropriate maintenance methods and normal examinations, these concerns can be identified and resolved efficiently to stop any type of disturbances in lift feature.

In guaranteeing the ideal capability of lift systems, vigilance towards the integrity of safety attributes ends up being critical complying with the recognition and resolution of control system problems - platform lift dimensions.In conclusion, typical concerns in lift repair consist of lift door concerns, electrical breakdowns, hydraulic system troubles, control system glitches, and safety and security functions concerns